Fixed & Replaceable Types of Membrane Filter Plates

Membrane filter plate has a chamber below the drainage surface that may be inflated. The common method used is water pressure, which is generated by pumping into the squeeze cavity to inflate the face of filter plate against the filter cake. Air pressure may also be used.

Membrane plates help reduce the filter cake moisture content and shorten cycle time of filtration. Two types of membrane plate designs are available: fixed membranes and replaceable membranes. Fixed membrane filter plate is manufactured by molding a face membrane and a core plate separately. The face membrane is then joined into the core by heat welding to form a homogeneous plate. Replaceable membranes use a polypropylene core, which is machined to accept the connection and seal of a rubber membrane. These faces are easily changed. Mixed pack membranes are the most common configuration (one recessed plate, and one membrane plate alternately arranged in the press plate pack). The final product saves operating cost in the overall plate pack.

One corner feeding membrane filter plate with size of 1600 mm.

One corner feeding membrane filter plate with size of 1250 mm.

One membrane filter plate with size of 2000 mm.

Rubber membrane filter plate has longer service life as the rubber membrane can not be easily damaged with high elasticity.

One kind of filter plate especially designed for beer industry.

Membrane filter plate can be made into this special design, with top feeding hole outside the plate.

The membrane filter plate can be made into four feeding holes outside the filter plate for some special uses.

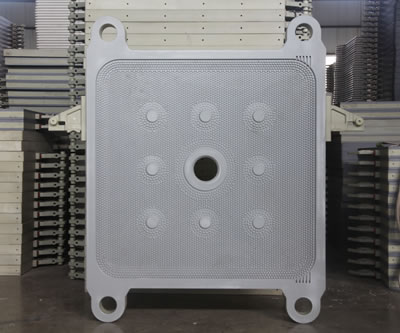

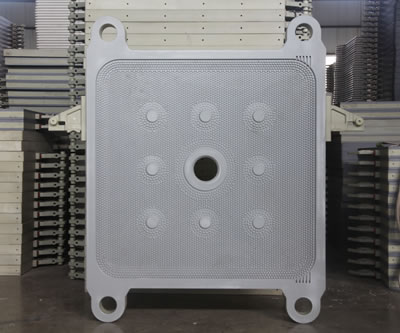

One central feeding filter plate with size of 1600 mm.

One membrane filter plate with size of 1500 mm.

One membrane filter plate with size of 1000 mm.

One membrane filter plate with size of 1250 mm.

One membrane filter plate with size of 800 mm.

This kind of replaceable membrane filter plate is widely used as the membrane is damaged, just replace the membrane instead of replacing a new membrane plate.

Feature

- Filtration with low pressure shortens filter cycle and improves productivity greatly.

- Cake-washing with middle or low pressure shortens washing cycle greatly and improves productivity greatly.

- Squeezing process with high pressure decreases moisture content of filter cake, reduces energy consumption and increases recovery ratio.

- Replaceable membrane filter plate has excellent sealing property, convenient demounting and replacement, which decreases production expenses greatly.

- Specialized processing technology with high quality imported material ensures long service life of filter plate.

Specification

- Material: rubber, polypropylene.

- Size: 800 mm, 1000 mm, 1250 mm, 1500 mm, 2000 mm. (Other sizes can be customized according to request.)

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.