Manual filter press is one kind of intermittent pressure filter used for solid-liquid separation of various suspending liquids. It is suitable for filtering in industries with small scale, which needs low filter pressure (≤ 0.4 MPa). With manually closing the filter plates and discharging cakes, manual filter press has low cost, easy operation and high filtration efficiency. It belongs to testing machine with small input quantity when used in laboratory. It is widely used in chemical industry, metallurgy, coal washing, pharmacy, food and other industries that need excellent filtered results.

Manual filter press components

Manual filter press is mainly composed of three parts: frame, filtration part and pressing section. When operating the filter press, rotates the hand-wheel through the pinion and bull wheel, driving the guide screw to impel the compaction board. It presses the filter plate and filter medium (filter cloth) tightly to guarantee pressure filtration in filter chamber for filtered material (slurry) carried with working pressure.

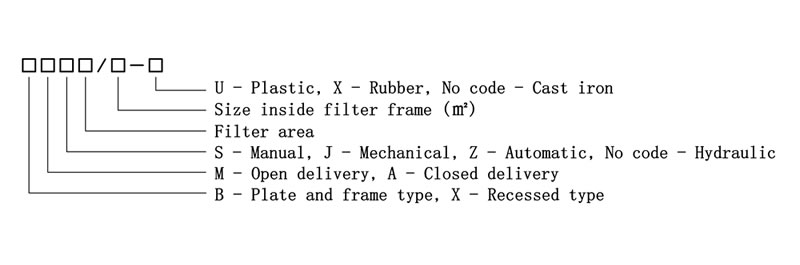

Manual filter press classification

There are two kinds of manual filter presses:

Working principle

As the filtering process begins, the slurry is pushed into each filter chamber through the feeding port of thrust plate under the impetus of feeding pump. The filter medium (filter cloth) retains the particles in the filter chamber, which forms into filter cake, while the filtrate is drained through the water nozzle (open delivery) or the fluid channel (closed delivery). Inject wash liquid through washing port of the thrust plate, if filter cake washing is needed.

Feature

Specification

| Model | Filter area (m2) | Filter plate (pcs) | Filter chamber volume (m3) | Dimension (mm) | Weight (kg) | Base dimension L2 (mm) | Maximum stroke (mm) |

|---|---|---|---|---|---|---|---|

| BMAS2/450-U | 2 | 5 | 0.03 | 1700 × 730 × 825 | 510 | 1110 | 400 |

| BMAS4/450-U | 4 | 9 | 0.06 | 1970 × 730 × 825 | 570 | 1350 | |

| BMAS6/450-U | 6 | 15 | 0.10 | 2340 × 730 × 825 | 660 | 1720 | |

| BMAS8/450-U | 8 | 19 | 0.12 | 2580 × 730 × 825 | 720 | 1960 | |

| BMAS10/450-U | 10 | 23 | 0.15 | 2820 × 730 × 825 | 790 | 2200 | |

| BMAS12/450-U | 12 | 29 | 0.18 | 3190 × 730 × 825 | 880 | 2570 | |

| XMAS2/450 | 2 | 5 | 0.03 | 1720 × 730 × 825 | 510 | 1100 | 400 |

| XMAS4/450 | 4 | 9 | 0.05 | 1940 × 730 × 825 | 570 | 1320 | |

| XMAS6/450 | 6 | 15 | 0.08 | 2270 × 730 × 825 | 650 | 1650 | |

| XMAS8/450 | 8 | 19 | 0.10 | 2500 × 730 × 825 | 710 | 1880 | |

| XMAS10/450 | 10 | 23 | 0.15 | 2720 × 730 × 825 | 780 | 2100 | |

| XMAS12/450 | 12 | 29 | 0.18 | 3060 × 730 × 825 | 860 | 2440 | |

| BMAS12/630-U | 12 | 15 | 0.21 | 2920 × 1100 × 1130 | 1400 | 2060 | 525 |

| BMAS15/630-U | 15 | 17 | 0.26 | 3050 × 1100 × 1130 | 1450 | 2190 | |

| BMAS20/630-U | 20 | 25 | 0.35 | 3580 × 1100 × 1130 | 1700 | 2720 | |

| BMAS25/630-U | 25 | 31 | 0.44 | 3980 × 1100 × 1130 | 1850 | 3120 | |

| BMAS30/630-U | 30 | 37 | 0.53 | 4370 × 1100 × 1130 | 2050 | 3510 | |

| BMAS40/630-U | 40 | 49 | 0.70 | 5160 × 1100 × 1130 | 2300 | 4300 | |

| XMAS12/630-U | 12 | 15 | 0.18 | 2910 × 940 × 1130 | 1400 | 2050 | 525 |

| XMAS15/630-U | 15 | 17 | 0.22 | 3030 × 940 × 1130 | 1450 | 2170 | |

| XMAS20/630-U | 20 | 25 | 0.30 | 3540 × 940 × 1130 | 1700 | 2680 | |

| XMAS25/630-U | 25 | 31 | 0.38 | 3910 × 940 × 1130 | 1850 | 3050 | |

| XMAS30/630-U | 30 | 37 | 0.45 | 4290 × 940 × 1130 | 2050 | 3430 | |

| XMAS40/630-U | 40 | 49 | 0.60 | 5050 × 940 × 1130 | 2300 | 4190 |

Operation procedure

Applications

Solid-liquid separation process in various industries such as:

Inquiry for Our Product

Boegger Industech Limited

E-mail:

info@filterpress.org

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Copyright © 2016 Boegger Industech Limited